Scroll saws are incredibly versatile tools that allow woodworkers and hobbyists to create intricate and detailed designs with precision. One of the most important aspects of using a scroll saw is choosing the right blade. The type of blade you use can greatly affect the quality of your cuts. It also impacts the material you’re working with and the intricacy of your project.

In this blog, we’ll explore some common types of scroll saw blades. We’ll discuss their characteristics and explain what they are best used for. Whether you’re a beginner or a seasoned woodworker, you should understand these blade options. This knowledge will help you take your scroll saw projects to the next level.

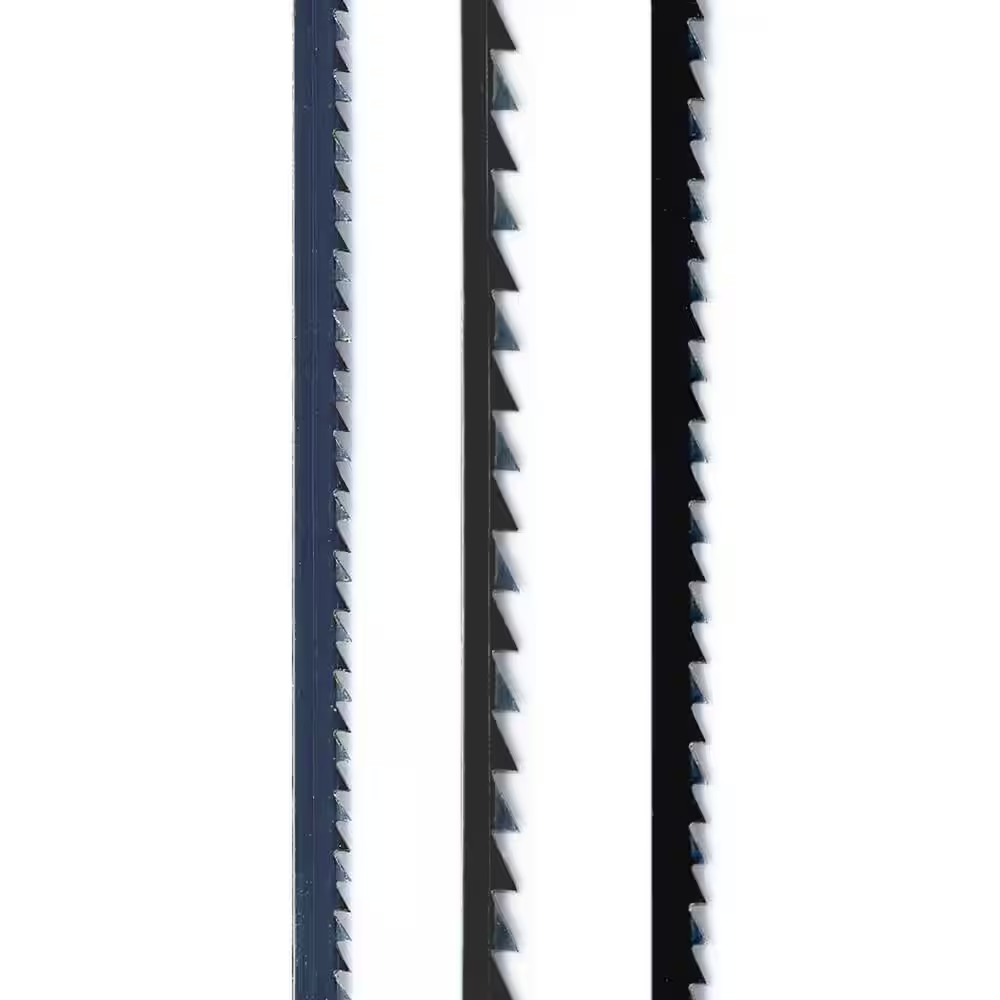

1. Flat Blades (Standard Blades)

Description:

Flat blades, also known as “standard” blades, are the most common type used for general-purpose scroll sawing. These blades have a straight, flat cutting edge and are usually made from high-carbon steel or tungsten.

Common Uses:

- Straight Cuts: These blades work well for making straight cuts in wood, plastic, and other materials.

- Thick Materials: They are ideal for cutting through thicker pieces of material without bending or flexing.

- General Crafts: If you’re working on general craft projects or cutting simple shapes, flat blades are a great option.

Pros:

- Durable and long-lasting

- Suitable for a wide range of materials, including wood, plastic, and metal

- Available in various sizes and tooth configurations

Cons:

- Not ideal for cutting curves or intricate designs

- Can leave rough edges if not used properly

2. Skip Tooth Blades

Description:

Skip tooth blades have teeth that are spaced farther apart than standard blades. The teeth are shaped like a “V”. They skip every other space. This design allows for faster cutting and better chip removal.

Common Uses:

- Cutting Curves: Skip tooth blades are great for cutting smooth curves, especially on soft woods.

- Thick Materials: They excel at cutting through thick materials with minimal resistance.

- Fast Cuts: If you need to cut through a piece quickly, skip tooth blades are a good choice. These blades are effective when detail is not a concern.

Pros:

- Cuts quickly and efficiently

- Reduced clogging due to wider tooth spacing

- Ideal for softwood and some thicker materials

Cons:

- Not the best for fine details or intricate designs

- Can leave a rough finish

3. Double-Tooth Blades

Description:

Double-tooth blades feature two teeth for every one space between them. This configuration helps provide a finer cut with less friction.

Common Uses:

- Fine Detail Cutting: Double-tooth blades are designed for cutting finer details and curves with greater accuracy.

- Thin Woods and Materials: They’re particularly effective when cutting through thin woods, plastics, or thin metal.

- Smooth Edges: If you need a cleaner cut without the need for excessive sanding afterward, double-tooth blades are ideal.

Pros:

- Produces smoother cuts with less sanding required

- Great for fine details and curves

- Works well on thin materials

Cons:

- Slower cutting compared to skip tooth blades

- Can get clogged more easily with thicker materials

4. Crown Tooth Blades

Description:

Crown tooth blades have a unique tooth design where the teeth resemble a crown (with a rounded, peaked shape). This design allows for smoother cuts with less resistance, making them particularly useful for more delicate work.

Common Uses:

- Intricate Work: Ideal for cutting small, detailed shapes and intricate designs.

- Hardwoods and Softwoods: These blades are versatile enough for both hardwoods and softwoods.

- Delicate or Fragile Materials: The crown tooth blade produces less vibration. It’s a good option for delicate materials like thin veneer or certain plastics.

Pros:

- Provides a smooth, clean cut

- Great for detailed or intricate projects

- Less vibration reduces the risk of splintering delicate materials

Cons:

- Slower cutting speeds compared to skip tooth blades

- May not be ideal for thick materials

5. Reverse Tooth Blades

Description:

Reverse tooth blades have teeth that face downward on the lower half. This design helps reduce splintering on the underside of the material. These blades are often used when you need a clean cut with minimal sanding on both sides of the material.

Common Uses:

- Cutting Thin Materials: Reverse tooth blades are excellent for cutting thinner materials like plywood, veneer, or MDF.

- Underside Finish: If you’re worried about splintering or tear-out on the underside of your cuts, you should consider using reverse tooth blades. These blades are the perfect solution.

- Fine Woodworking: Ideal for projects where both the top and bottom of the material need to be clean and smooth.

Pros:

- Reduces tear-out on the underside of materials

- Provides a clean cut on both sides

- Ideal for thinner materials or fine woodworking

Cons:

- Slower cutting than regular tooth blades

- May not work as well on thick or dense materials

6. Spiral Blades

Description:

Spiral blades are unique in that they cut in all directions—360 degrees around the blade. They have a twisted, spiral shape, which allows for cutting in any direction without the need to rotate the material.

Common Uses:

- Cutting Tight Turns: Spiral blades excel at cutting tight curves and intricate patterns, as they don’t require turning the material.

- 3D Work: They are useful for cutting shapes from all angles, making them great for 3D projects.

- Small Parts: Ideal for cutting small, detailed pieces, especially when cutting out multiple shapes or parts from a single sheet.

Pros:

- Cuts in any direction, allowing for maximum flexibility

- Great for tight curves and intricate cuts

- Can be used for 3D cutting or cutting out complex shapes

Cons:

- Can be harder to control compared to other blade types

- Tends to produce a rougher finish, requiring additional sanding

- Not ideal for straight cuts

Conclusion

The type of scroll saw blade you choose will significantly impact your projects. It’s important to match the blade to the material you’re cutting. Consider the level of detail you require. Understand the characteristics and best uses of each blade type. Whether it’s a standard flat blade, a fine-toothed blade for intricate detail, or a spiral blade for tight curves. This knowledge ensures your scroll saw projects are both efficient and precise.

Don’t be afraid to experiment with different blades to see which one works best for your specific needs. Happy sawing!