When it comes to woodworking, precision and attention to detail are essential. One of the most useful techniques that can elevate both the functionality and aesthetics of a project is chamfering. Chamfering, though often overlooked, is a straightforward yet valuable process that makes a big difference in the overall look and performance of your wood projects. Whether you’re working on furniture, cabinetry, or decorative pieces, chamfering can enhance the visual appeal and safety of your work. In this blog, we’ll dive into what chamfering is, why it’s important in woodworking, and how to achieve perfect chamfers.

What is Chamfering in Woodworking?

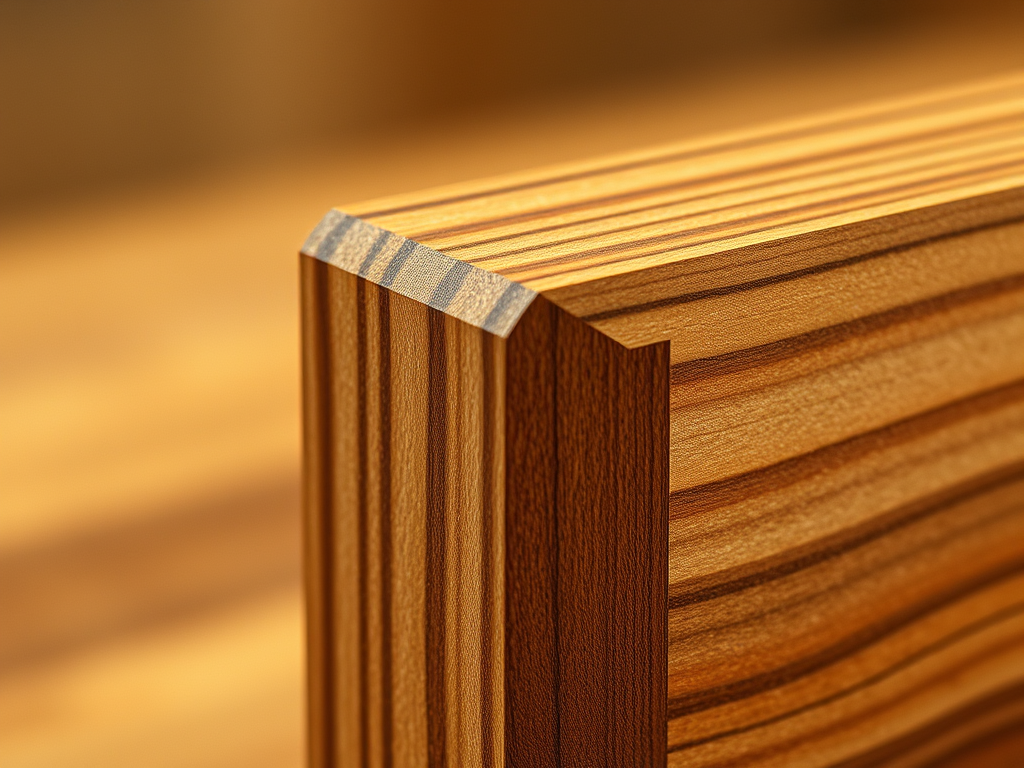

Chamfering in woodworking refers to the process of cutting or beveling the sharp edges of a piece of wood at an angle, usually 45 degrees, though other angles may be used depending on the desired effect. The result is a sloped edge that replaces a sharp corner, creating a smoother, softer transition between two surfaces.

Unlike rounding over edges, where the corners are curved, chamfering leaves a flat, angled cut. Chamfering can be done on a variety of wood types, whether softwood, hardwood, or plywood, and can be applied to furniture pieces, cabinet edges, picture frames, molding, and many other wooden items.

Why Chamfering is Important in Woodworking

Chamfering offers several practical and aesthetic benefits that make it a must-have technique in woodworking. Here are a few key reasons why chamfering is important:

1. Enhanced Aesthetics

Chamfered edges add a touch of sophistication and refinement to your woodworking projects. The clean, angled edges give a modern, polished look to everything from furniture to trim work. Whether you’re crafting a sleek coffee table or finishing off the edges of a wooden frame, chamfering helps create a more visually appealing result.

2. Improved Safety

Woodworking can be hazardous if sharp edges are left exposed. Chamfering softens these sharp corners, reducing the risk of injury during handling or use. For example, a chamfered edge on a wooden shelf or drawer can prevent snagging or accidental cuts, making your finished pieces safer for both builders and users.

3. Better Fit and Alignment

Chamfered edges are easier to assemble and fit together. When joining two pieces of wood, such as when creating a box or a frame, chamfering the edges ensures the parts come together more smoothly. The beveled edges guide the pieces into alignment, reducing the chance of misalignment or imperfect joints.

4. Durability and Wear Resistance

Sharp edges on wood can become worn or damaged more easily over time, especially on frequently used items like tables, chairs, and cabinets. Chamfering helps prevent damage to the edges, improving the overall durability of your work. The chamfered edges are less likely to chip, crack, or show wear, ensuring your projects stand the test of time.

5. Ease of Finishing

Chamfering edges also improves the application of finishes, such as varnish, paint, or stain. The angled edges are less likely to show brush marks or streaks, which can be more apparent on sharp corners. Furthermore, chamfering provides a cleaner, more uniform look when the wood is stained or painted.

How to Chamfer in Woodworking

Chamfering can be done with a variety of tools, depending on the project and the level of precision you require. Here are the most common methods for chamfering wood edges:

1. Hand Tools

For smaller projects or when working with delicate pieces, hand tools like a chamfer plane or block plane can be used to carefully shave off the edge at the desired angle. These tools offer great control, making them ideal for fine woodworking or when working with softwood or thin materials. A hand-held files or rasps can also be used to manually smooth and shape the chamfer.

2. Router

A router is one of the most versatile tools for chamfering edges on wood. With the right router bit, you can quickly create precise chamfers on any edge of your workpiece. A chamfer bit with a bearing guide is commonly used for this purpose. You can set the depth of the cut and control the angle to achieve a uniform chamfer along the entire edge. Routers are especially useful for larger projects and for achieving consistent results.

3. Table Saw

A table saw can also be used to chamfer edges, particularly on larger pieces or when working with thicker wood. By tilting the saw blade to the desired angle (typically 45 degrees) and running the wood through, you can create chamfered edges efficiently. This method is ideal for projects that involve straight cuts or long edges, such as shelving, molding, or paneling.

4. Miter Saw

For more precise chamfers, especially on pieces with angled cuts, a miter saw can be used. By adjusting the saw’s angle, you can create consistent chamfered edges on your workpiece. This method is particularly useful for projects like framing, door or window trim, and molding.

5. Chisels and Scrapers

For small projects or more intricate details, chisels and scrapers can be used to manually create chamfered edges. While this method takes more time and effort, it allows for a great deal of control, which is essential for custom work or when working with intricate patterns.

Chamfering Applications in Woodworking

Chamfering can be applied in a variety of woodworking applications. Here are some common uses of chamfering in woodworking:

1. Furniture Making

Chamfering is commonly used on the edges of furniture like tables, chairs, cabinets, and shelving. It softens the harshness of sharp corners, making furniture more comfortable to handle while enhancing its visual appeal.

2. Trim and Molding

In trim work, chamfered edges are often used on moldings, baseboards, and window casings to give a clean, decorative finish. The chamfered edge can also allow moldings to fit more securely together.

3. Cabinetry

When constructing cabinetry, chamfering can be applied to the edges of doors, drawer fronts, or the outer edges of cabinet boxes. It adds both style and functionality, creating smooth joints and more refined details.

4. Picture Frames and Decorative Woodwork

Chamfering is also a popular technique in decorative woodwork and when creating picture frames. It adds depth and interest to the frame’s profile, making the piece more eye-catching without being overly ornate.

Conclusion

Chamfering may seem like a simple technique, but it plays a vital role in woodworking by improving the aesthetics, safety, and functionality of your projects. Whether you’re crafting a piece of furniture, installing trim, or simply refining the edges of a project, chamfering can make a significant difference. With a variety of tools available, it’s easy to achieve the perfect chamfer on any woodworking project, giving your work a professional and polished finish.

Next time you’re in the workshop, remember that a little chamfering can go a long way in enhancing the quality and beauty of your woodworking projects!